Since Automationspartner started in 1994, we have worked with catheter forming. With this extensive knowledge and experience regarding the forming of catheters, we offer services to support our customers in their development.

Our Forming Method

With our generators we use electromagnetic induction to quickly reach precise temperatures. The temperatures are controlled and regulated separately for each mold with a closed loop temperature feedback. We thermoform our catheters with high speed, high precision and high quality. We use high quality materials and components for our catheter forming solutions which ensures long term high quality, low maintenance costs for high volume production. With AP there is always a future high volume production in mind and our technology can be scaled up.

Our services

We offer support of forming catheters for various purposes and of various materials. We support our customers with development of catheter tip forming and forming of other parts of the catheters. In our automation test lab, we have equipment setup for testing and development of catheter geometries. We also offer production of samples for studies and animal testing in an ISO 8 cleanroom environment (particle measured, not bio-burden). The sample production in our facilities allows quicker design changes and an overall faster development cycle.

Insulin / Subcutaneous Catheters

We offer support of forming catheters for subcutaneous use such as long-term insulin injection. Customer specific tip geometries and materials can be tested and developed in our lab. We also offer production of samples for studies and animal testing in an ISO 8 cleanroom environment (particle measured, not bio-burden). The sample production in our facilities allows quicker design changes and an overall faster development cycle.

Different variants of materials such as PP, FEP and PUR is commonly formed but other materials can also be tested as long as they are thermoformable.

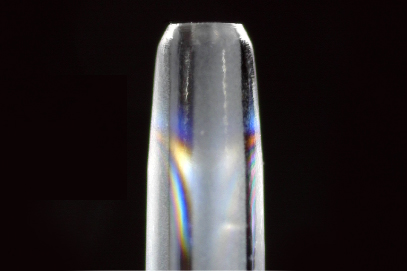

Infusion / IV or Arterial Catheters

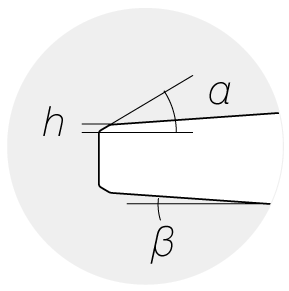

We offer support of forming IV Catheters. Customer specific tip geometries with specific qualities such as peel back and penetration force. The qualities are developed, tested and documented in our lab. We also offer production of samples for studies and animal testing in an ISO 8 cleanroom environment (particle measured, not bio-burden). The sample production in our facilities allows quicker design changes and a faster development cycle.

Different variants of materials such as FEP and PUR are commonly formed but other materials can also be tested as long as they are thermoformable.

The catheter tip design and quality are two of the most important factors in superior IV access. Our tip geometry evaluation is based on results from penetration test and peel back testing. The tip design is optimized based on these two results.

Urinary / Intermittent Catheters

We offer support of forming Urinary / Intermittent Catheters. Samples can be produced for studies in an ISO 8 cleanroom environment (particle measured, not bio-burden). The sample production in our facilities allows quicker design changes and an overall faster development cycle. With AP forming technology tip geometries can be formed in high speed, with a high quality and repeatability.

Different variants of materials such as PVC, PP, FEP, PUR and TPE is commonly formed but other materials can also be tested as long as they are thermoformable.

We also offer hole / eyelet punching support. We help our customers develop and test various variants of punched holes and eyelets in the catheters.