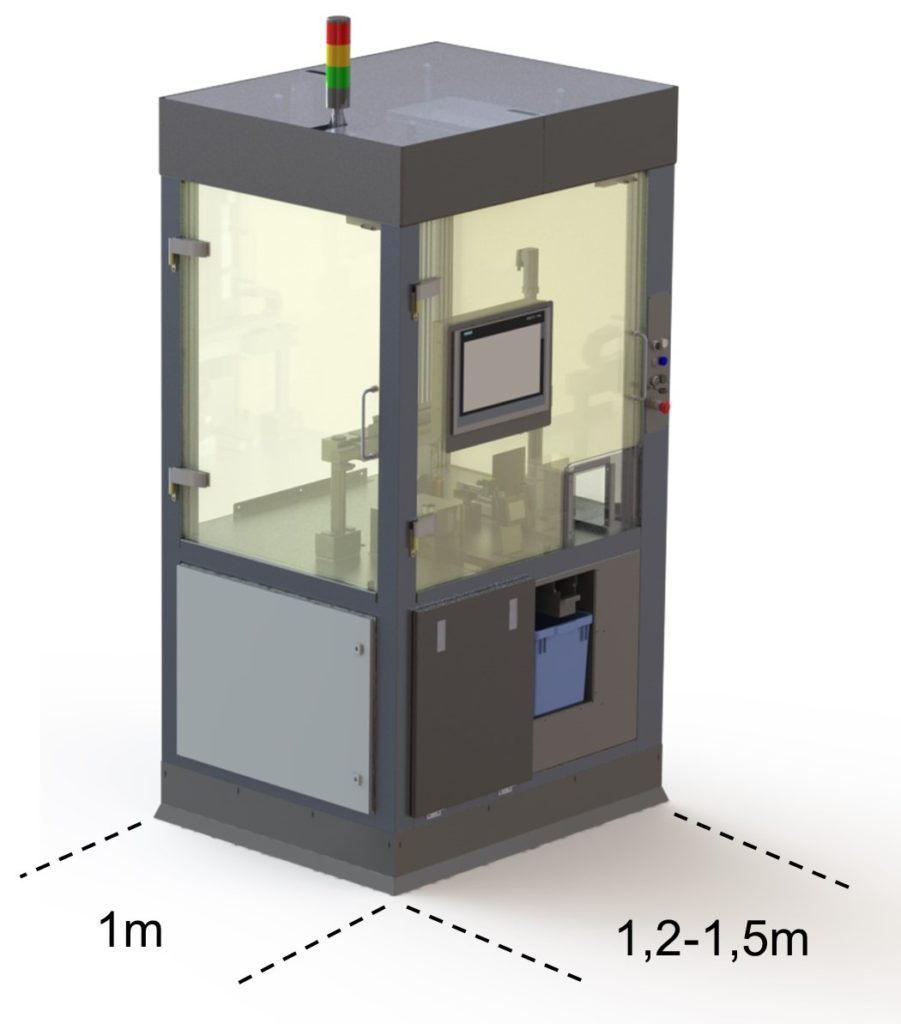

Our Solution

The SA-41 and SA-61 automated autoinjector test system from Automationspartner ensures a precise product quality control and is easy to operate. The SA fulfills requirements by relevant authorities which state that combination products (autoinjectors) must be tested by the legal manufacturer prior to batch release. The test system is designed for GMP ISO Class 8 production environments and performs the testing according to the ISO-standards. The system is designed for autoinjectors such as the Molly and DAI autoinjectors from SHL Group, and the Ypsomate autoinjector from Ypsomed. Autoinjectors with similar designs can also be tested in the system. Four to six autoinjectors can be loaded into the system for automated testing (more as an option). Automationspartner also offers the same functionality in automated in-line process control (IPC) systems, integrated into our autoinjector assembly lines.

Benefits

- Quick batch releases close to the production line

- Operator QA competence not needed

- Standard automation components ensure a flexible solution

- Easy to adapt to specific customer requirements

- PLC platform ensures software stability

Rapid Testing in 2.5 min

Our automated autoinjector test systems streamline your autoinjector assembly line. Within 2.5 minutes, the system can load four autoinjectors, run all standard tests on each unit and output the results in a batch report.

Compliance

- ISO-11608

- 21 CFR Prt 11

- CE machine directive

Function

Standard Injector Tests

- Protective cap removal force

- Needle cover pre-injection force — If push button activated

- Activation force — Needle cover activation or push button

- Injection time — Liquid dispensing time measurement

- Dose accuracy — Precise weighing of dispensed liquid

- Injection depth — Measurement of needle extension during liquid dispensing

- Needle cover override force and displacement — Attribute test

Optional Tests and Functions

- Separation Force — Attributes test G/NG, performance vs spec.

- Graphs of test values – High speed sampling accuracy

- Secure encrypted communication to other systems (OPC-UA)

- Verification of correct product through barcode or QR-code

- Customer-defined number of devices to be loaded

- Product in-feed from trays

Delivery

- FAT & SAT

- Installation

- Operator training

- Thorough documentation

- Remote access support

- IQ & OQ (Option) Service agreement (Option)

Autoinjector Test System Footprint

The SA-41 and SA-61 automated autoinjector test system is compact with a small footprint.