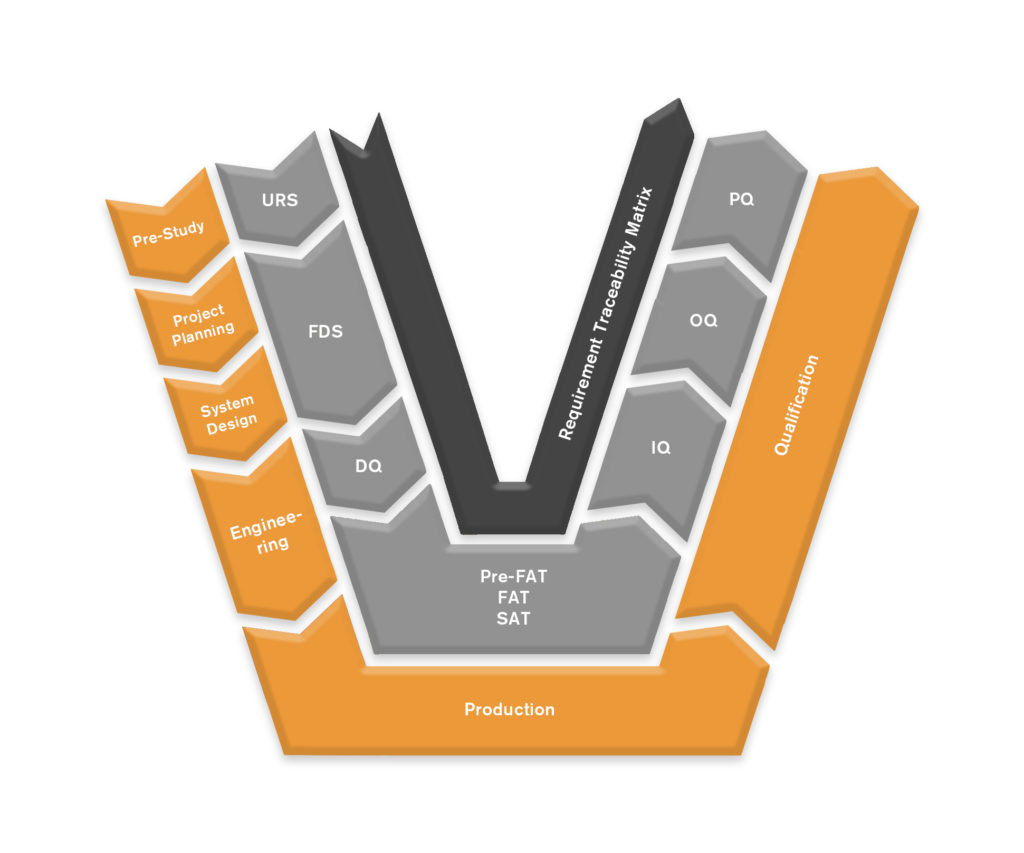

Our engineers and technicians deliver support services within qualification and validation of production processes. As a leading developer of automated production processes, with an in-depth understanding of GMP, ISO 13485 and GAMP5, the AP team is well suited to make a difference in your Medtech project.

We can join customer project teams as members for shorter or longer periods of time, or we can be assigned to deliver specific QA tasks.

- Developing technical documentation and test protocols (SAT, FAT plans)

- Risk analysis and CE-marking

- Review, analysis, and re-qualification of processes in order to improve and stabilize production

- Developing URS (User Requirements Specification) for customers investment projects

- Review of implemented QA control methods; validate or test?

Quality Assurance

- Design robustness

- DFM/DFA analysis

- Review of key processes and critical technologies

Test Documentation

- FAT – Plan, Perform and document

- SAT – Plan, Perform and document

- IQ & OQ – Plan, Perform and document

URS Support

- Identifying customer needs

- Understand and specify critical functions

- Authoring URS according to GAMP